Durable Home Cost Calculator

Calculate long-term savings of durable building materials compared to traditional wood construction. Based on data from the article "What Is the Most Durable House to Build?".

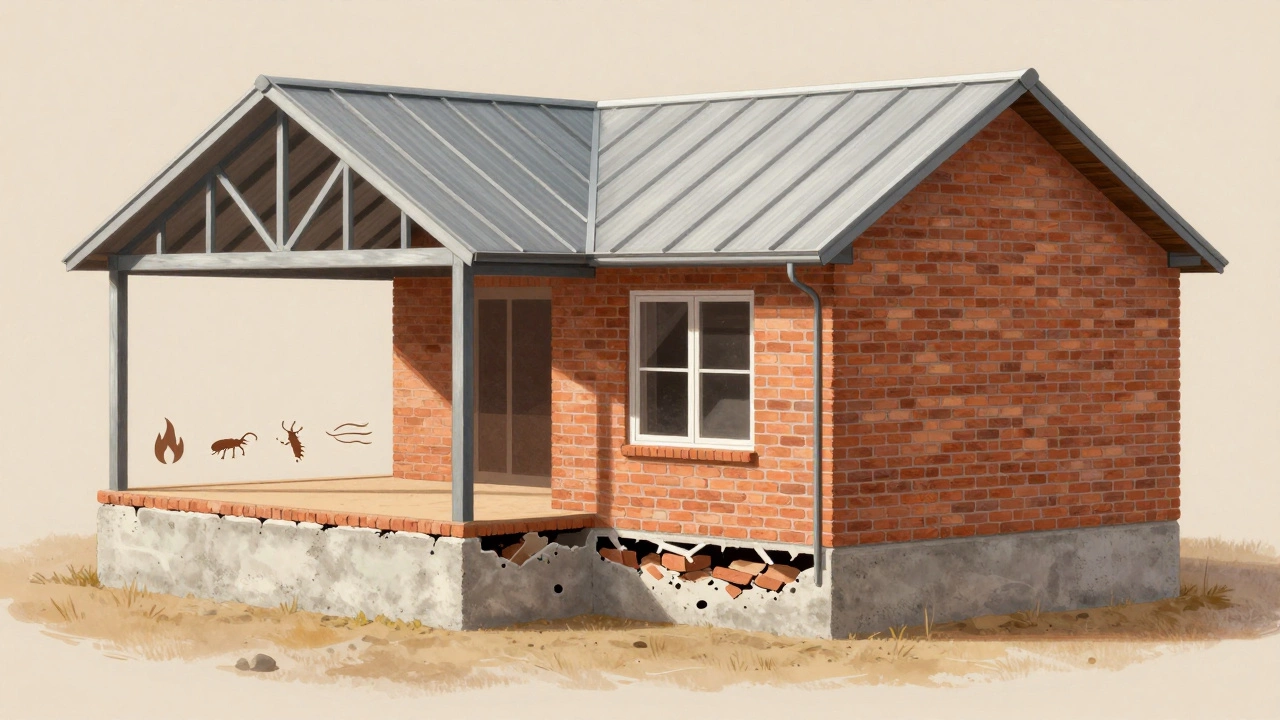

When you’re building a house from scratch, you don’t just want it to look good-you want it to last. Not just for 20 years, but for 50, 100, or even longer. Weather, pests, fire, earthquakes, and time all wear down homes. But some materials and designs stand up to all of it. So what’s the most durable house to build? The answer isn’t just one material. It’s a smart combination of design, foundation, and construction choices that work together to resist damage over decades.

Concrete: The Unshakable Base

Concrete is the backbone of the most durable homes built today. Not just any concrete-reinforced, high-density, poured-in-place structural concrete. Homes built with concrete walls, floors, and roofs can survive hurricanes, wildfires, and even direct lightning strikes. In Florida, after Hurricane Ian in 2022, homes built with insulated concrete forms (ICFs) had 90% less structural damage than wood-frame homes nearby. That’s not luck. That’s physics.

Concrete doesn’t rot, warp, or attract termites. It resists mold and mildew when properly sealed. A well-built concrete home can last 100+ years with minimal maintenance. The key is in the details: proper curing, steel rebar reinforcement, and drainage systems around the foundation. Skip these, and even concrete can crack. Get them right, and your house becomes nearly indestructible.

Steel Framing: The Hidden Strength

While concrete handles the bulk of the load, steel framing adds another layer of durability. Steel is 10 times stronger than wood per pound and doesn’t expand or contract with humidity. That means no squeaky floors, no sticking doors, no warped trim. Steel frames also resist fire better than any wood-based system. In a fire, wood burns. Steel bends-but doesn’t collapse-until it hits 1,100°F, far above what most house fires reach.

Steel framing is used in commercial buildings for a reason. It’s also becoming popular in high-end residential builds, especially in coastal areas where salt air eats through wood. A steel-framed house won’t sag over time. It won’t attract carpenter ants or dry rot. And unlike wood, it won’t warp in the sun. The only downside? Higher upfront cost and the need for skilled installers. But over 50 years, the savings on repairs and insurance make it worth it.

Masonry: Brick, Stone, and Block That Lasts

Nothing says durability like brick. Homes built with solid brick walls in the 1800s are still standing today. Modern brick veneer isn’t the same-it’s just a thin layer over wood framing. But full-thickness masonry, like load-bearing brick or stone block walls, is a different story. These homes don’t need internal framing. The walls themselves hold up the roof.

Stone masonry, especially when laid with lime mortar (not modern cement), can last 300+ years. Lime mortar is breathable, allowing moisture to escape instead of trapping it and cracking the stone. Many historic homes in England and Italy use this technique. Modern versions use engineered stone blocks with reinforced cores, making them even stronger.

Block homes-concrete blocks filled with rebar and grout-are common in hurricane zones. They’re cheaper than solid brick but just as strong. In Texas and Louisiana, code now requires block construction for new homes in high-risk areas. Why? Because after Hurricane Harvey, homes built with block had far fewer structural failures.

Insulated Concrete Forms (ICFs): The Best of Both Worlds

ICFs are the smartest innovation in durable home building this century. They’re foam blocks stacked like LEGO bricks, then filled with concrete. The foam stays in place, acting as insulation, soundproofing, and a vapor barrier. The concrete gives you strength. The result? A home that’s energy-efficient, quiet, fire-resistant, and nearly impervious to storms.

ICF homes use 50% less energy than traditional wood homes. They can withstand winds over 200 mph. In 2023, a study by the National Institute of Standards and Technology found that ICF homes suffered 87% less damage in tornado tests than wood-frame homes. And they’re getting cheaper. In 2025, the cost gap between ICF and wood framing has narrowed to just 8-12% higher, thanks to mass production and better labor training.

ICF homes are the go-to for builders who want maximum durability without sacrificing comfort. They’re not just for disaster zones anymore. More homeowners in colder climates like Minnesota and the UK are choosing them for their thermal mass-staying warm in winter, cool in summer-without cranking the AC.

Why Wood Isn’t the Answer, Even If It’s Popular

Wood is cheap. Wood is easy. Wood is everywhere. But it’s not durable. Wood rots. Wood attracts termites. Wood burns. Even pressure-treated lumber only delays the inevitable. In humid climates, wood homes start showing signs of decay in 15-20 years. In dry climates, they crack and warp. In coastal areas, salt air eats away at nails and framing.

Yes, you can build a beautiful wood house. But if your goal is longevity, wood is a compromise. It needs constant maintenance: paint every 5-7 years, termite treatments, moisture checks, roof inspections. Over 50 years, that adds up to tens of thousands in repairs. A concrete or masonry home? A quick pressure wash every few years and maybe resealing the joints. That’s it.

Foundation Matters More Than You Think

A house is only as strong as its foundation. Even the best walls will fail if the base shifts. The most durable foundations are either full-depth poured concrete or reinforced concrete piers. Slab-on-grade foundations work in stable soil but can crack in areas with expansive clay. Basements are great if you’re in a cold climate, but only if they’re waterproofed properly.

In London, where the soil is clay-heavy and rainfall is frequent, builders now use deep pilings with reinforced concrete footings. This keeps the house from sinking or tilting over time. A poorly built foundation can cause cracks in walls, sticking doors, and uneven floors within a decade. A well-built one? It lasts the life of the house-and then some.

Roofing and Exterior: The First Line of Defense

Even the strongest walls can be defeated by a bad roof. Metal roofing is the most durable option. It lasts 50-70 years, resists fire, sheds snow and rain, and doesn’t crack under freeze-thaw cycles. Asphalt shingles? They last 15-25 years. Tile roofs are beautiful but heavy and brittle. Wood shakes? They rot.

Exterior cladding matters too. Fiber cement siding (like HardiePlank) is the best alternative to wood. It’s fireproof, termite-proof, and won’t warp. Vinyl siding is cheap but can crack in extreme cold. Stone veneer adds durability and curb appeal without the weight of full masonry.

What About Green Building? Can It Be Durable Too?

Yes-but only if you choose the right materials. Straw bale homes, for example, can be incredibly energy-efficient and sustainable. But they require perfect sealing and drainage. If moisture gets in, the straw rots. Bamboo is strong, but it needs chemical treatment to resist insects and decay. These materials can work, but they demand expert design and maintenance.

For true durability, combine green goals with proven materials. Solar panels on a metal roof? Great. Geothermal heating in an ICF home? Perfect. Rainwater harvesting with a concrete cistern? That’s smart. Sustainability doesn’t mean sacrificing strength. It means choosing materials that last, so you don’t have to rebuild.

Final Verdict: The Most Durable House to Build

The most durable house to build today combines four things: a reinforced concrete foundation, ICF or masonry walls, steel framing for the roof and floors, and a metal roof. That’s the winning combo. It’s not the cheapest upfront. But over 50 years, it saves you money, stress, and heartache.

Think of it this way: if you’re building a house to live in for the rest of your life-or to pass down to your kids-would you bet on wood and shingles? Or would you bet on something that can outlast storms, fires, and time?

There’s no magic material. But there is a smart combination. And that’s what makes the most durable house.

Is a concrete house cheaper to build than a wood house?

No, a concrete house usually costs 8-15% more upfront than a wood-framed house. But over 30-50 years, it costs less. Concrete homes need far less maintenance, have lower insurance premiums, and use 40-50% less energy. Many homeowners break even on the initial cost within 15 years.

Can you build a durable house in a cold climate?

Yes, and in fact, cold climates benefit even more from durable materials. Concrete and ICF homes retain heat better than wood. Steel doesn’t become brittle in freezing temps. Metal roofs handle heavy snow loads without collapsing. In places like Canada or northern England, durable homes are not a luxury-they’re a necessity.

Do durable homes look modern or can they be traditional?

They can look like anything. Concrete walls can be finished with stone, stucco, or wood accents. Brick and masonry homes have been built for centuries in classic styles. Steel framing can support any roofline or window layout. Durability doesn’t mean sacrificing style. It means building something that lasts, no matter the design.

Are there any government incentives for building durable homes?

Yes. In the UK, the Green Homes Grant and local council schemes offer rebates for energy-efficient builds, including ICF and high-performance insulation. In the U.S., tax credits are available for solar-ready homes and homes built to withstand extreme weather. Check with your local building authority-many offer lower permit fees for code-compliant, durable construction.

How long does it take to build a durable house compared to a regular one?

It takes about the same time. Concrete and ICF walls may take a few extra days to cure, but the overall timeline is similar. Steel framing goes up faster than wood in some cases. The real difference isn’t in build time-it’s in what happens after. A durable house takes less time to maintain and repair over decades.

What to Do Next

If you’re planning a new build, start by talking to a builder who’s worked with ICF or masonry. Ask to see past projects. Check if they’ve built in high-wind or flood zones. Don’t just pick the cheapest quote-ask why they recommend certain materials.

Get a soil test before laying the foundation. Know your climate risks. Then choose materials that match. A durable house isn’t about being flashy. It’s about being smart. And the smartest choice is one that lasts.