When you buy a new house, you expect it to be solid, safe, and built to last. But too many new builds come with hidden structural problems that don’t show up until it’s too late. A structural defect isn’t just a cracked tile or a squeaky floor-it’s something that threatens the safety and stability of the whole building. These defects can cost tens of thousands to fix, and in worst-case scenarios, make a home unsafe to live in.

What Counts as a Major Structural Defect?

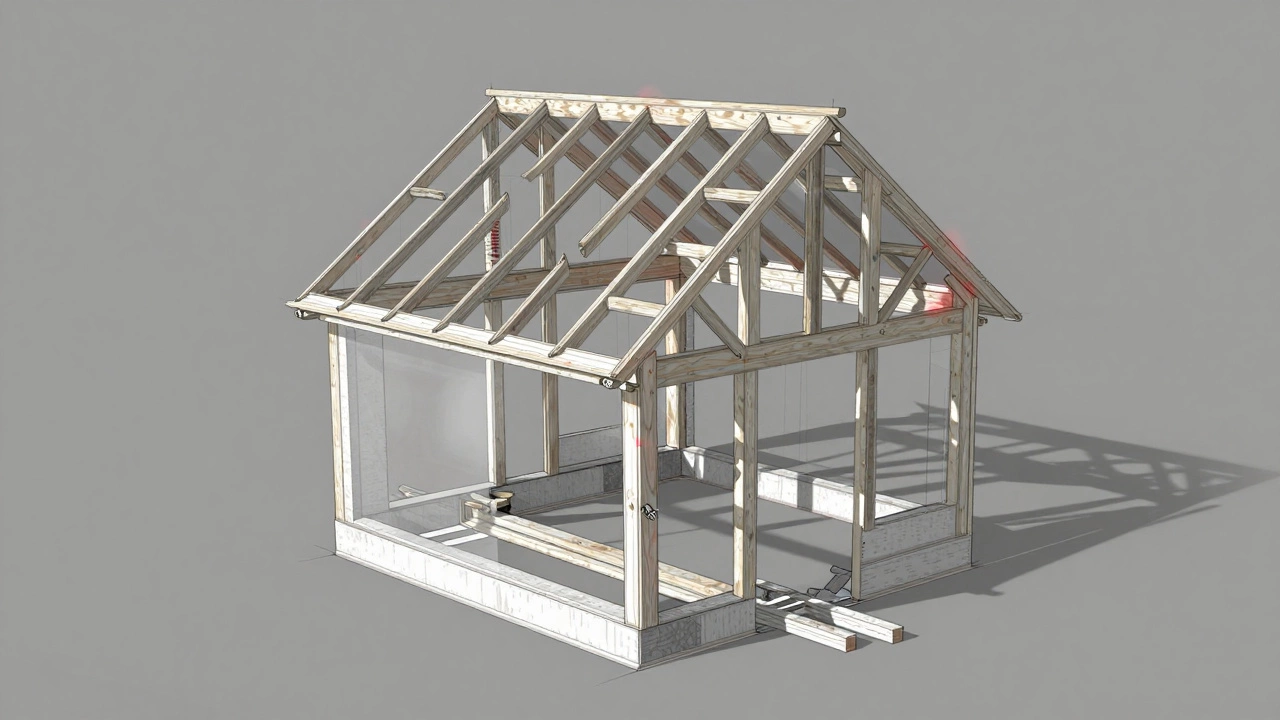

A major structural defect is any flaw in the core load-bearing parts of a house that compromises its ability to support weight, resist forces like wind or earthquakes, or stay upright over time. This includes the foundation, main beams, load-bearing walls, roof trusses, and the connections between them. It’s not about aesthetics. It’s about physics.

Think of a house like a human skeleton. If your spine is misaligned, you can’t stand straight. If your foundation shifts, the whole structure leans, cracks, or worse. In new builds, these problems often come from rushed work, cheap materials, or poor design-not always from outright fraud. Builders under pressure to meet deadlines sometimes cut corners on things you can’t see until it’s too late.

Top 5 Major Structural Defects in New Builds

Not all defects are equal. Some are common. Some are deadly. Here are the five most serious structural flaws found in newly constructed homes:

- Foundation cracks and settling-Not all cracks are normal. If cracks are wider than 1/4 inch, run diagonally across walls, or appear on both interior and exterior walls, they signal uneven settling. In new builds, this often happens because the soil wasn’t properly compacted before pouring the slab, or the footing depth didn’t meet local code.

- Improperly sized or spaced framing-Wall studs, floor joists, and roof rafters must follow strict spacing rules (usually 16 or 24 inches on center). If builders use undersized lumber or space members too far apart, floors sag, walls bow, and ceilings crack under normal weight. I’ve seen homes where joists were 2x6 instead of 2x8, and the floor dropped 2 inches in two years.

- Missing or weak load-bearing supports-Load-bearing walls and beams carry the weight of upper floors and the roof. If a builder removes a wall to open up a living space without installing a proper beam, the structure can collapse. In one case, a new build in Texas had a 12-foot span with no beam-just two 2x4s nailed together. It gave way during heavy rain.

- Roof truss failures-Trusses are engineered to distribute weight evenly. If they’re damaged during transport, improperly installed, or cut to fit a duct or chimney, they can buckle. Look for sagging ceilings, especially near the center of the house. A single truss failure can bring down an entire section of the roof.

- Water damage hidden in walls-Leaky roofs, poorly flashed windows, or missing housewrap can let water into the framing. Over time, this causes rot in studs, joists, and sheathing. In new homes, this often goes unnoticed because drywall is installed before inspections catch it. Mold is a symptom-the real danger is the weakened wood behind it.

Why New Builds Are Especially Vulnerable

You’d think new means better, but that’s not always true. In 2024, the National Association of Home Builders reported that 38% of new homes in the U.S. had at least one structural issue found during the first-year warranty inspection. Why?

- Speed over quality-Many builders use assembly-line methods to cut costs. One crew does the foundation, another the framing, another the roofing. Communication breaks down. Mistakes pile up.

- Subcontractor turnover-Framers and roofers are often hired on short-term. If they’re paid by the job, not by quality, they’ll rush. I’ve seen roofs nailed with 1.5-inch nails instead of 3-inch, because the crew ran out of time.

- Inadequate inspections-Most inspections happen before drywall goes up. If a defect is hidden behind walls or under flooring, inspectors miss it. And in some states, builders can self-certify work, meaning no third-party check happens at all.

How to Spot a Structural Defect Early

You don’t need to be an engineer to catch warning signs. Here’s what to look for before you sign the papers:

- Check doors and windows-If they stick, won’t close, or are crooked, the frame is shifting.

- Walk through the house barefoot-Feel for uneven floors. A slope of more than 1/2 inch over 10 feet is a red flag.

- Look for stair-step cracks in brick or block walls-These run diagonally and often mean the foundation is sinking.

- Examine the attic-Are the rafters bowed? Is there a gap between the truss and the ridge beam? That’s a sign of under-engineering.

- Check the basement or crawl space-Look for water stains, warped wood, or rust on steel supports. Moisture is the silent killer of structure.

Take photos. Write down where you see issues. Don’t rely on the builder’s word. Get a licensed structural engineer to inspect the home before closing. It costs $500-$800, but it could save you $50,000 later.

What to Do If You Find a Defect

If you’re in a new build and you spot a major structural issue, act fast:

- Document everything-Photos, videos, notes, dates.

- Notify the builder in writing-Keep a copy. Don’t just call.

- Request a structural engineer’s report-This is your leverage.

- Review your warranty-Most new homes come with a 10-year structural warranty (builder’s warranty). This covers foundation, load-bearing walls, and roof framing.

- File a claim with your state’s construction board-Many states have recovery funds for homeowners with uncorrected defects.

Don’t wait. Structural damage only gets worse. A small crack today can become a collapsed ceiling tomorrow.

Preventing Structural Defects Before You Build

If you’re planning a custom build, don’t just pick the cheapest bid. Here’s how to protect yourself:

- Hire an independent inspector for each major phase-foundation, framing, rough-in, final.

- Require stamped engineering drawings-All load-bearing elements should be designed by a licensed structural engineer.

- Check the builder’s track record-Ask for three recent homes they built and visit them. Look for cracks, sloping floors, and sticking doors.

- Insist on soil testing-If the ground shifts, your house will too. A simple compaction test costs $200 and prevents foundation failure.

- Use a construction loan with inspection milestones-This gives you control. Payments are released only after each phase passes inspection.

Building a home should be exciting, not risky. A well-built house lasts 50+ years. A poorly built one becomes a money pit.

Final Thought: It’s Not Always the Builder’s Fault

Some defects come from bad codes, bad materials, or bad weather. But most come from poor oversight. The system is designed to move houses quickly-not perfectly. That’s why you can’t rely on the builder to catch everything. You have to be your own advocate.

Structural defects don’t show up on Instagram tours. They show up in the silence between the walls. Pay attention to what’s hidden. Your safety depends on it.