If you want to see what truly holds our world together, don’t look up at the latest architectural icon. Take a closer look at what’s under your feet, behind your walls, and above your head. There are just three heavy hitters that have shaped nearly every structure around you: concrete, steel, and wood. They’re the backbone of every city, home, office, and even that local chippy you duck into when London’s rain comes down sideways. It’s impressive how these humble materials play a starring role in every skyline and street. But it’s not just about function: each one has a personality, quirks, and a story that stretches back centuries. If you’re thinking of building something, or just want to tackle the pub quiz, you’re about to get the lowdown on the real stars of construction.

Concrete: The Modern-Day Stone

You’d struggle to find a street in London that doesn’t have concrete underfoot. Walk past St. Paul’s and that smart-looking pavement is probably made of it. The stuff is everywhere because it’s tough, kind of like the reliable mate who’ll help you move house no matter what. Concrete mixes cement, sand, gravel, and water into a paste that sets rock-hard. What makes it the champion material? Strength, for starters: concrete can take a beating, withstand the wildest weather, and it’s fire-resistant—a handy feature whether it’s for tower blocks or backyard patios.

But hang on—concrete is more than just brute strength. Builders love it because they can pour it into any shape. Those curvy bits on London’s new high-rises? That’s concrete, behaving nicely for the architects’ wild ideas. It also lasts forever—well, sort of. The Romans used a form of concrete two millennia ago, and their aqueducts are still standing. Not many materials can say that.

Now, concrete isn’t perfect. Mixing it releases carbon dioxide, so it’s not winning any environmental prizes. Researchers are racing to make eco-friendlier versions, with mixes that use less cement or even absorb CO₂ over time. This is big, as cement production alone makes up around 8% of the world’s carbon emissions—no small number. If you’re planning a new build or even just a garden path, there are now greener options like fly ash or slag-based concretes. These not only reduce emissions but can actually improve durability in some cases.

Ever wonder why concrete cracks? It’s all about moisture and temperature swings. The trick is in the prep: use the right mix ratios, add steel reinforcement (more on that later), and take care during curing—letting the concrete set slowly, instead of baking under the summer sun. Little things, big difference. London’s Crossrail project, for example, used thousands of kilometres of reinforced concrete, all precisely managed to avoid cracks and keep things safe for generations.

And here’s a fun bit: concrete can look beautiful. Look at The Barbican, brutalist as it is, or peek at polished concrete floors in a Shoreditch loft. With dyes, special finishes, and clever craftsmanship, it’s not just grey and grim. It’s got style and substance.

Steel: The Skeleton of Structures

Steel is where things get serious. Without steel, we’d have no Gherkin, no Shard, none of London’s tall glass towers standing defiant against the weather. Those dramatic city skylines? That’s steel at work, quietly holding everything together. Steel is made mainly from iron and carbon. With a bit of chemistry and plenty of heat, you get something that’s both strong and flexible. That means it can support dizzying loads and still sway a little in strong winds—vital when you’ve got a forty-storey apartment block.

One of steel’s biggest tricks is its speed. Prefabricated steel beams arrive on-site ready to go, slotting together like a grown-up’s Meccano set. There’s far less waiting around than with concrete. Steel is often used in frames, columns, and all those hidden skeletons that transform a pile of blueprints into a place where people actually live and work.

It’s also recyclable. You might walk past a building in central London made partly from steel that’s older than your grandparents—melted down and reborn more times than anyone can count. In fact, about 90% of structural steel gets recycled at end of life. That’s a big win for anyone worried about waste.

Steel’s not just about brute force and big bills, though. It’s precise. Architects choose steel when a building needs to look light, airy, even futuristic. All-glass facades need something steady behind them, and that’s usually a web of steel beams, hidden from sight but utterly essential. Modern stadiums, railway stations, bridges—none of these icons would exist without it.

There’s a flip side, though. Steel loves a good rush of fresh air, but too much means rust, especially in a city as damp as London. The trick? Protective coatings and clever design—galvanised finishes, weathering steel that forms a protective layer of rust, and regular maintenance that stops things going pear-shaped. If you’re ever tempted to skimp on these, think again. Corrosion can do real damage.

One last quirk: steel is sensitive to heat. At extreme temperatures, it can lose strength (that’s why fires in steel buildings are such a hazard). That’s why you’ll see lots of insulation, fireproofing paint, and even concrete or brick wraps on major city structures. Planners here know you can’t risk shortcuts.

Wood: Nature’s Original Building Block

You might not spot timber front and centre in London’s skyline, but look closer—walk down a residential road, step inside nearly any pre-war house, or wander into a cool café with chunky beams overhead. Wood is everywhere. It’s easy to forget just how versatile and renewable it is. The oldest buildings still standing—from medieval cottages to certain country pubs—are often built from massive oak beams, lovingly joined and pegged by hand.

Wood gets some good marks: it’s light, it insulates well, and it locks away carbon for the life of the building. That last bit’s getting more important as everyone tries to go greener. Timber-frame houses are on the rise again in the UK, popping up from London to Manchester, all promising smaller carbon footprints and beautifully warm interiors. Early in 2025, the government even talked up new incentives for extra-energy-efficient timber homes to meet carbon targets.

If you thought wood was boring, think again. There’s good old pine and oak for walls and floors, but now we’ve got engineered wonders: plywood, OSB, and most excitingly, cross-laminated timber (CLT). CLT acts a bit like super-plywood—big sheets glued together in different directions, making them incredibly strong but still easy to work with. CLT and other mass timbers are behind a new generation of mid-rise (and even high-rise) wooden buildings. Murray Grove in Hackney, built back in 2009, is eight floors of pure timber—and still looks fresh as ever.

The catch? Moisture is wood’s archenemy. If left out in the rain without good treatment, it rots and warps. Most modern timber gets a protective soak in preservatives or clever coatings, but you’ve also got to be careful with design: avoid contact with the ground, keep the air moving, and don’t let water pool up. Most timber is certified now (think FSC or PEFC labels), so you know it comes from well-managed forests. This is worth checking—cheap, un-certified wood might save pennies now but cost a fortune in repairs later.

Last tip: don’t panic about fire. Properly treated and used in thick-enough sections, wood chars on the outside and actually protects the inner core. That’s why many fire regulations accept CLT for all sorts of projects these days.

Other Contenders and Their Perks

The big three—concrete, steel, and wood—cover most buildings, but you’ll spot other materials in supporting roles. Bricks still line many homes across the UK, and new types like aircrete blocks offer loads of insulation. Glass fills modern towers with daylight, but advanced coatings now keep out unwanted heat and block UV. Plastics, from pipes to window frames and modern roofing, are everywhere because they’re light and easy to mould to shape.

Stone is a traditional favourite, especially on fancy facades and landmark buildings. The grand steps outside the British Museum? Yorkshire limestone. Natural stone is gorgeous, though expensive and tricky to source sustainably.

Each material brings something new to the mix. Aluminium, for example, is catching on as a steel rival for certain frames and facades—super-light and rust-proof, but it takes loads of energy to produce. Modern composite materials blend the best parts of plastic and glass fibres for strong, super-light components—used a lot in roofs, bridges, and high-performance cladding systems.

If you’re planning your own project, think about maintenance, not just the upfront look and cost. Mixing materials—say, a steel frame with concrete panels and timber cladding—can get the best of all worlds, but only if each layer is compatible. Pay attention to how different materials move, swell, or contract as the weather shifts: mismatched joints make trouble.

And don’t forget about sustainability and local rules. London’s building codes get stricter every year. More projects now use recycled aggregates in concrete, or specify UK-grown timber over imports. Always ask your builder or supplier what’s available, and look for real evidence—like EPDs (Environmental Product Declarations)—to back up any green claims.

Choosing the Right Material for Your Build

Picking your building blocks isn’t just about what’s cheapest or fastest to install. The choice affects how your space looks, how it feels in winter (and sticky London summers), whether you’ll be dealing with leaks or cracks, and even how much the building will cost you in upkeep decades from now.

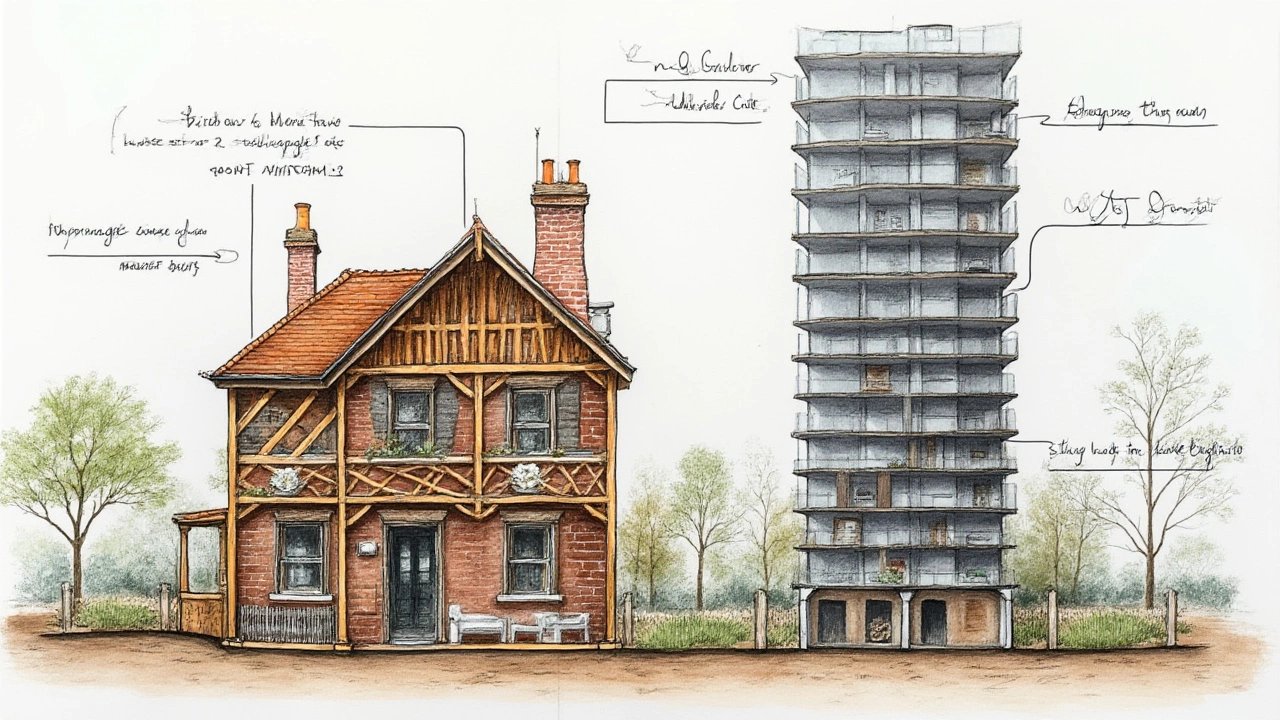

If strength and fire resistance are crucial—think big apartment blocks, offices, or public buildings—concrete and steel will form the backbone. Homes and smaller builds might lean more on wood, especially as timber technologies advance and people chase lower-carbon living.

Don’t underestimate location and weather. In a damp, rainy city, proper protection for steel and wood is a must, while concrete needs good drainage and careful curing. For buildings in high-traffic spots, exposed brick or stone can take a beating and look smart for ages—but you’ll pay more upfront.

Think long-term: what happens if you want to renovate one day? Steel frames are easy to adapt, while major concrete walls can make alterations trickier. Wood can be rebuilt fairly simply, but needs extra TLC.

Joining the sustainable building trend isn’t just about feeling good, either. With energy bills soaring, timber’s natural insulation might save you cash every winter, while high-efficiency windows and smarter use of recycled materials will impress even the fussiest buyers.

Above all, don’t skimp on professional advice. An architect or structural engineer will keep your dreams doable—and head off disasters you might not spot, like hidden weak points, unwanted heat loss, or the slow creep of rot or rust. Buying the best *construction materials* now pays off every year you use the space. Next time you step outside your door, pay attention: every building is the result of tough choices, clever innovations, and a toolkit that goes back to the basics—concrete, steel, and wood. No structure’s perfect, but with the right mix, you’ll get something that endures long after the dust settles.