Epoxy Injection: The Simple Way to Fix Floor Cracks

If you’ve ever stared at a hairline crack in a concrete floor and thought it would spread, you’re not alone. Most people assume the only fix is a big demolition job, but there’s a quieter, faster method: epoxy injection. This technique pours liquid epoxy into the crack, fills the void, and hardens into a solid bond that behaves like the original material.

Why Choose Epoxy Injection?

First, it’s cheap compared with tearing out and replacing concrete. You pay for the material and a few hours of labour, not for a whole new slab. Second, it’s quick. A skilled team can finish most residential jobs in a single day, so you’re not stuck without a floor for weeks. Third, the repaired area regains its original strength. Epoxy is strong enough to handle foot traffic, vehicle loads, and even heavy equipment in commercial settings.

Another plus is that the process works from the inside out. The epoxy binds the crack faces together, preventing water, chemicals, or dirt from slipping through. That means you protect the underlying structure from future corrosion or rot. For homeowners worried about indoor air quality, epoxy is a low‑odor product that cures without releasing harsh fumes.

How the Process Works

Step one is inspection. A professional will walk the floor, locate all cracks, and test their width with a crack gauge. Most cracks between 0.1 mm and 5 mm are perfect candidates. Wider gaps might need a different method, but the inspector will let you know.

Next comes cleaning. The area around the crack is vacuumed or brushed to remove dust, debris, and loose particles. Clean surfaces let the epoxy adhere properly.

Then the epoxy is prepared. It usually comes in two parts – resin and hardener – that mix just before injection. Modern kits have a handheld pump that pushes the liquid into the crack at low pressure. As the epoxy fills the void, it pushes air out through a vent port, ensuring a complete fill.

Once the crack is full, the technician seals the entry points with a surface sealant. The epoxy cures in about 30 minutes to an hour, depending on temperature. After curing, the floor can be sanded, stained, or covered with a new finish if desired.

Bad news? Not many. The only time epoxy injection isn’t ideal is when the crack is moving constantly, like on a shifting foundation. In those cases, a more flexible filler or structural repair may be needed. But for static cracks caused by shrinkage or minor settlement, epoxy injection is the go‑to solution.

At First Choice Flooring Solutions we’ve used epoxy injection on everything from a kitchen floor in a London flat to a warehouse slab in Manchester. Our crew follows the same step‑by‑step routine, so you get a reliable result every time.

Thinking about cost? Expect a price range of £30‑£70 per linear meter, depending on crack depth and floor access. That’s a fraction of the £200‑£400 per square metre you’d pay to replace the whole slab.

Ready to stop worrying about cracks? Give us a call, and we’ll schedule a quick site visit. We’ll point out any problem areas, explain the injection process, and give you a clear quote. No hidden fees, no surprise delays.

Epoxy injection isn’t just a repair; it’s a preventive measure that keeps your floor solid and looks good for years. Whether you own a cosy home or a busy commercial space, the method saves you time, money, and hassle.

Best Foundation Crack Repair: What Actually Works?

- Gavin Whitaker

- |

- |

- 0

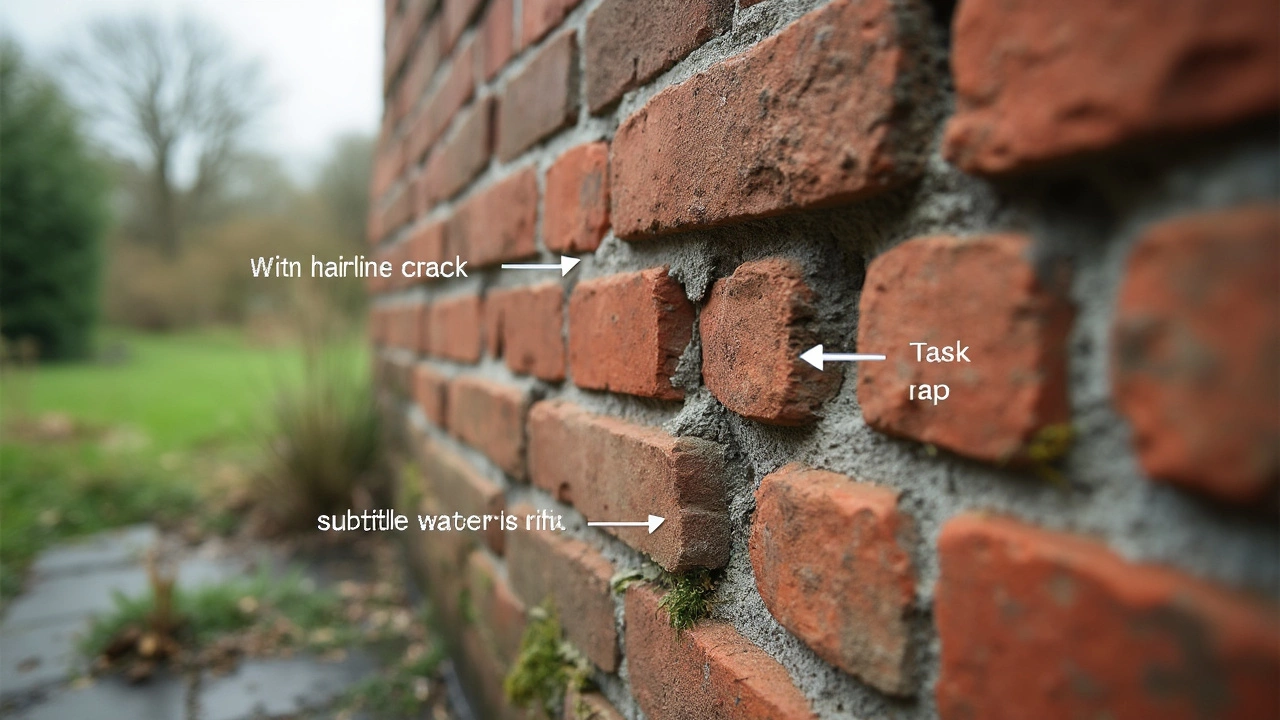

Foundation cracks look scary, but not all repairs are the same. This article breaks down the main ways to fix foundation cracks, explains which methods work best for different situations, and covers pros, cons, and what to watch out for. You'll learn simple warning signs, get money-saving tips, and understand when it's time to call an expert. Whether it's a thin hairline crack or a wider gap leaking water, you'll know your options before you even call a contractor.

View more